The most critical factor that determines the quality of the production process is the good implementation of the production procedures. These procedures are applied very tightly and controlled in Varzene Metal. With the help of computer-aided hot forming programs, each alloy family is reproduced homogeneously and proportionally throughout the diameter ranges. These programs guarantee the standardization of material properties.

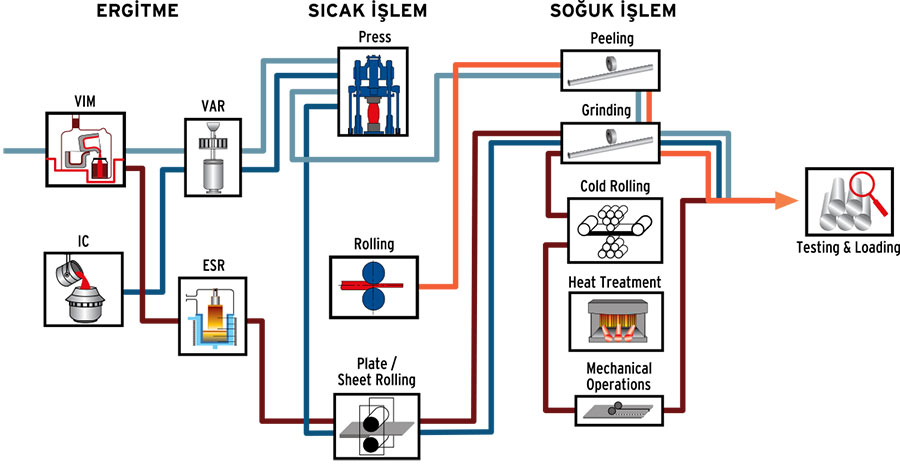

Varzene Metal production facilities are Continuous Casting, Vacuum Induction Melting (VIM), Vacuum Arc Melting (VAR), Open Induction Melting (IF), Vacuum Cup Induction Melting (VCAP) and Open Die Forging, Heat Treatment, Rolling, Cold Drawing and Mechanical Machining.