AZ91 Alloy and Its Use in Automotive Industry

31.01.2020

Varzene Metal

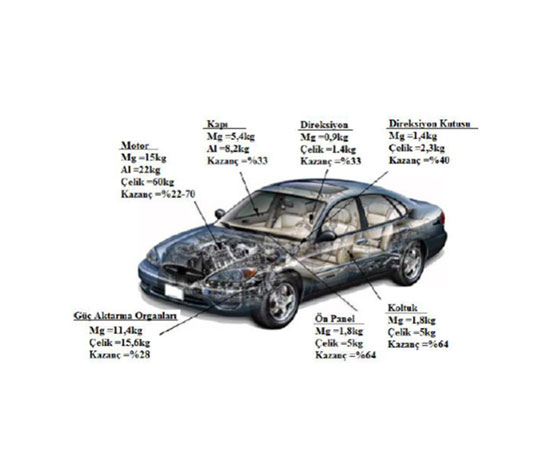

In recent years, AZ series casting Magnesium alloys, especially AZ91 alloy, have been used in some structural components of automobiles and aircraft for reasons such as high specific strength, lightness, environmental friendliness, conductivity. Volkswagen, one of the first to use these alloys, used approximately 22 kg of magnesium alloy in the Beetle model vehicle it produced in the 1970s.

Today, magnesium average use and per vehicle usage growth has continued to increase as 3 kg, 20 kg and 50 kg for 2005, 2010 and 2015, respectively.

For structural applications, as instrument panels where collapse is important, for steering systems and seating structures, magnesium molded AM50 or AM60 cast alloys are unique. It has high ductility advantage (10-15% elongation) and impact strength.

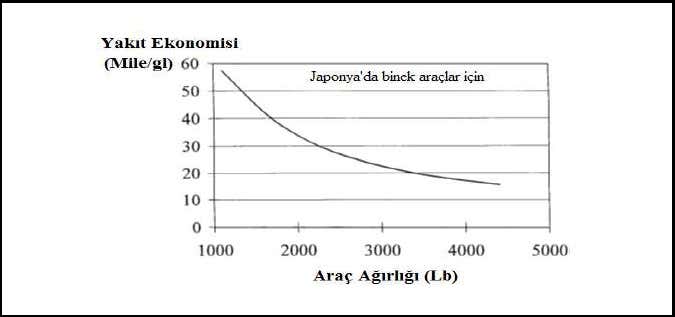

The main purpose of using magnesium (Mg) alloys is to achieve weight loss, energy saving and environmental limiting effect. The purpose of reducing weight is to improve vehicle performance by reducing fuel consumption and emission values, and also to significantly reduce CO2 emissions. However, vehicles can only be made lighter by using low density and strength materials. In this regard, the automotive industry has turned to new materials and has started giant long-term projects related to magnesium. Global trends force automotive manufacturers to produce lighter, environmentally friendly, comfortable, safe and economical vehicles. As of 2019, in a sedan vehicle with an average of 1200 kg, fuel consumption has been reduced to 3.9 lt / 100 km and CO2 emissions below 99 g / km. In the near future, even more significant reductions in fuel consumption and CO2 emissions are predicted by significantly reducing vehicles.

Figure 1: Weight advantages of magnesium in vehicles compared to steel and aluminum

Figure 2: Fuel Economy / Vehicle Weight Diagram

References:

1- ALTUNOK Kenan , Kocaeli university, Use of magnesium alloys in automotive industry and the latest technological developments, 2019

2- MERT ,Faruk , ÖZDEMİR Ahmet ,Gazi Üniversitesi, Magnezyum Alaşımlarının Basınçlı Dökümü ve Otomotivdeki Uygulamaları,2011