VAR Process

13.05.2020

Varzene Metal

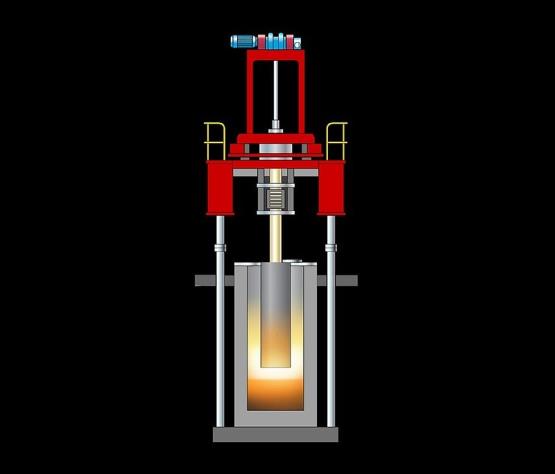

Effects and Benefits of Vacuum Arc Remelting (VAR) Process

The methods used in melting and pouring very high quality steels consist of high quality and high-tech processes. The properties that determine the quality in high quality steels depend on the following factors;

• Narrow chemical composition

• Homogeneous chemical composition

• Fine-grained and homogeneous microstructure

• Machined surfaces (Peeled off)

In addition to the usual steel making processes, very clean scrap (especially stainless steel scrap) is used as input. The melting process is carried out in Electric Arc Furnaces (EAF) and after melting, alloying and degassing with ladle metallurgy, Ca injection etc. processes are applied to the melt to improve the quality of the steel.

Casting is done by bottom casting method for the same purpose. The ingots obtained in this way are re-melted and the internal structure homogeneity is further increased, then they are forged and heat treated. Here, the microstructure of the forged steel is modified and the billets go into machining to remove the weathered layers that form on the surface during both forging and heat treatment. Thus, these logs, which become peeled off, are then subjected to ultrasonic crack control and made ready for other mechanical examination.

The ladles used in the bottom casting method have a bucket-shaped trunnion steel wall. These crucibles are generally brick-paved, sometimes used in plain form and sometimes with fire clay on the surface. At the bottom of the wall there is a hole with a refractory nozzle and inside this nozzle there is a plug to control the flow of metal.

With the ladle metallurgy and bottom casting system applied to high quality steels, segregations (accumulation of alloy elements and residues in certain areas) are reduced.

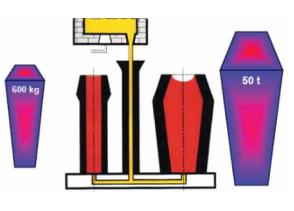

Benefits of Vacuum Arc Remelting (VAR) process; The VAR process helps to produce ultra-clean material, reduces segregation and inclusions in steel or other alloys, corrects them and improves grade properties. The benefit of Vacuum Arc Remelting is less gas and oxide content, increasing the homogeneity of the resulting ingots; improved ductility; more uniformity of features in the transverse and longitudinal directions; improved fatigue properties; and the integrity of the chemical composition.

VAR grade materials are found in aerospace applications, including "superalloys" required for extreme temperature and pressure applications. VAR steels are used in rocket booster rings, landing gear and high pressure pipes. In addition to oil and gas, the nuclear industry is used for re-melting reactive metals and alloys.

REFERENCES

Union of Turkish Engineers and Architects Chamber of Metallurgical Engineers