What Makes Super Alloys Super?

30.07.2020

Varzene Metal

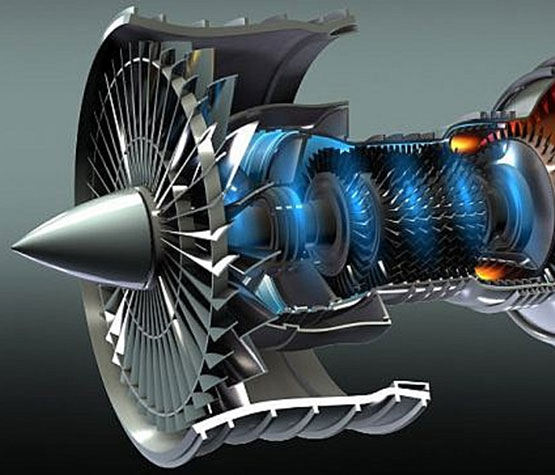

Hierarchical Microstructure of a Super Alloy

Researchers first observed in detail how a hierarchical microstructure developed during the heat treatment of a superalloy.

Materials in high performance turbines not only withstand strong mechanical forces, but also have to maintain their chemical and mechanical properties to almost melting points. For this reason, turbine manufacturers have been using special nickel-based high performance alloys for decades. The new work of Materialien und Energie from Helmholtz-Zentrum Berlin (HZB) now offers tips on how new phases in the form of nickel-based alloys developed and can be developed. Florian Vogel, PhD student from HZB Institute of Applied Materials and Dr. Nelia Wanderka elegantly combined the two methods to perform this transmission electron microscopy (TEM) and atomic probe tomography (APT), which they conducted in collaboration with colleagues from the University of Münster.

They dealt with a phase separation phenomenon that has been known for nearly 50 years but has not been fully observed or understood so far: The microstructure of nickel-based alloys changes under controlled aging or heat treatment, and new phases are initially formed in the classical two-phase microstructure. Wanderka and Vogel were able to fully observe the phase separation on an atomic scale for the first time.

To do this, they imitated the aging process by applying heat treatment to the alloy at different periods. They documented how the microstructure changed during the aging of the alloy using micrographs from the transmission electron microscope. The classical two-phase microstructure consists of cuboid γ 'sediments called γ-matrix, during the heat treatment spherical γ particles are formed initially in γ' sediments of the alloy, and then γ sediments. The thermo-mechanical properties of such alloys largely depend on the stability of this γ / γ´ microstructure.

To identify the atomic components of the individual phases, but first to learn about the formation and regulation of the particle that is not well understood, Vogel and Wanderka investigated aged samples using atomic probe tomography at the University of Münster. They were able to reconstruct the atomic lattice of the samples layer by layer and determine the composition of all phases so that they could explain the chemical evolution of γ particles.

“So far, it has been assumed that the partitioning of γ particles refine the microstructure during aging, which will be beneficial for the stability of the alloy under thermo-mechanical load. We were able to show that this is not true. The microstructure really changes significantly, but it does not heal by cleavage. In fact, we were able to associate the best mechanical properties with the presence of spherical or plate-like γ particles, not with the stages after the separation of γ sediments” explains Florian Vogel. Nelia Wanderka adds: "If we want to improve the stability of the microstructure and thereby the thermomechanical properties of the alloy, we must make sure that the γ precipitates are not separated by the γ particles, but instead remain intact with the combination of the appropriate heat treatment and alloy. Atom probe tomography helps us understand the role of the alloy elements in the formation and growth of γ particles. From this, we can learn how to affect these processes."

References: Florian Vogel, Nelia Wanderka, Zoltan Balogh, Mohammed Ibrahim, Patrick Stender, Guido Schmitz, John Banhart. Mapping the evolution of hierarchical microstructures in a Ni-based superalloy. Nature Communications, 2013; 4 DOI: 10.1038/ncomms3955