What is Monel?

28.06.2020

Varzene Metal

What is Monel?

It is the trade name of the alloy, which was created in 1901 by an engineer of the International Nickel Company (INCO), and contains mostly minimum 63% nickel, maximum 34% copper and added elements such as iron, manganese and sulfur.

What are the Properties of Monel Alloy?

Monel contains small amounts of iron, manganese, carbon and silicon, while "mainly" consists of nickel (52-67%) and copper (25-45%). It is a nickel alloy. Alloys with a copper content of 60% or more are called cupronickel. Stronger than pure nickel, Monel alloy is a solid solution binary alloy. Since nickel and copper are mutually soluble in all proportions, they are single-phase. Therefore, salt water corrosion resistance and high temperature resistance are very good. It is resistant to corrosion and acids, as well as some alloys even pure oxygen combustion. They are generally used in applications with intense corrosive conditions. It is very useful in a wide variety of corrosive environments such as sea currents. With the addition of small amounts of aluminum and titanium, "Monel K-500" is obtained with the same corrosion resistance, but much higher strength depending on the gamma primer formation with aging. It is difficult to machine compared to steel as Monel hardens very quickly. It should be rotated at low speeds and the feed rate should be low.

Where does the name Monel come from?

Monel was created in 1901 by chief metallurgist Robert Crooks Stanley, who worked for the International Nickel Company (INCO). Monel 400 alloy is a binary alloy with nickel and copper naturally present in meteoritic nickel ore from the Sudbury mine and therefore considered a pure alloy. Monel got its name from the company's president, Ambrose Monell, and was patented in 1906. Since family names were not allowed to be used as a trademark at that time, an L was omitted from the name.

Where are Monel used?

Since Monel is a single phase alloy, salt water corrosion resistance and high temperature resistance are very good. However, its high nickel content makes it an expensive material. It is much more expensive than stainless steel. Simple areas are avoided due to its high cost. Thanks to its corrosion resistance, it is highly preferred in marine and oil production applications. Its formability is quite good. In addition, thanks to its high temperature resistance feature, it is used in the protection of safety cables in aircraft, experimental rockets and aviation industry.

Aerospace: In the 1960s, Monel alloy was widely used in aircraft construction, especially in the construction of the roof and outer surfaces of experimental rockets such as the North American X-15, as it can withstand the great heat caused by aerodynamic friction during extreme flight. Since Monel alloy does not lose its strength at very high temperatures, it can keep its shape at high atmospheric flight speeds. On the other hand, the piece weight increases due to the high density of Monel. Monel is often used in high temperature areas for safety cables in aircraft maintenance to ensure fasteners do not come loose. In other places, more economical stainless steel is preferred. It is also used in the security wire system that prevents the unlocks from being opened in aircraft.

Petroleum Industry: Monel is used in direct contact with concentrated hydrofluoric acid in the alkylation units section. It offers outstanding resistance to hydrofluoric acid in all concentrations up to boiling point. It is probably the most durable of all commonly used engineering alloys. The alloy is also resistant to many forms of sulfuric and hydrochloric acid under reducing conditions. In the past, Monel alloy drill pipes were used in oil exploration wells. These drill pipes were preferred for drilling directional wells that needed good management. This would result in quicker and more accurate exploration, reducing hazards, and reducing the cost of directional drilling and controlled oil wells. The cost was reduced because of the ability to conduct real-time research with a drill gauge with magnetometers attached to them. Magnetometers should always be stored in a non-magnetized material so that they are not affected by the environment while reading the earth's magnetic field and that they can measure accurately. However, Monel is rarely used in directional drill pipes today. Although they are still called Monel tubular, non-magnetic stainless steel has been replaced for economic reasons.

Marine Industry: Monel's corrosion resistance makes it ideal for applications such as piping systems, pump shafts, marine valves and strainer baskets. Some alloys are completely anti-magnetic and are used in fixing cables, magnetic field measuring slots in mine scanners. In hobby boating, Monel wire is preferred to catch clamps in anchor ropes. It is also common in water and fuel tanks and underwater applications. It is also used for propeller shafts and bolts on boat keels. Popular Hobiecat sailboats have Monel rivets where strength is required. Stainless steel cannot be used here due to corrosion problems caused by the stainless steel in contact with the aluminum pole, boom and boat frame in the saltwater environment. However, when Monel is used in shipbuilding due to its electrolytic problem in salt water, it should be especially isolated from other metals such as steel. According to a report in the New York Times in 1915, a 65-meter yacht that was first completely manufactured from Monel was "dismantled" and scrapped in just six weeks. The reason was that the bottom was separated by electrical actions. The steel frame of the yacht had decomposed due to electrolytic interaction with Monel.

Other Applications: Monel was recommended for use in superheated steam systems in the early 20th century, when steam power was widely used.

RotoSound introduced Monel as an electric guitar wire in 1962, and these wires were used by many artists from Iron Maiden to Sting. Today, Monel continues to be used by many musical wire manufacturers. In addition, it is still used as a valve piston material in some high quality musical instruments such as trumpets, tuba and horn.

Parts of the Long Now Watch, which started operating on December 31, 1999 and is planned to work for 10,000 years, are made of Monel due to corrosion resistance without the use of precious metals.

Monel has been used in the production of Kelvinator refrigerators.

During World Wars, Monel was used even on military tags.

Today, it is used in a wide variety of industries, from kitchen sinks to spectacle frames, from the cinema industry to punch connections in photochemical tanks. Good resistance to acid and oxygen induced corrosion makes Monel a good material for the chemical industry as well.

You may be surprised, but scientists use Monel in their research, especially in the bands or rings they wear on many species such as albatross birds living in corrosive seawater environments.

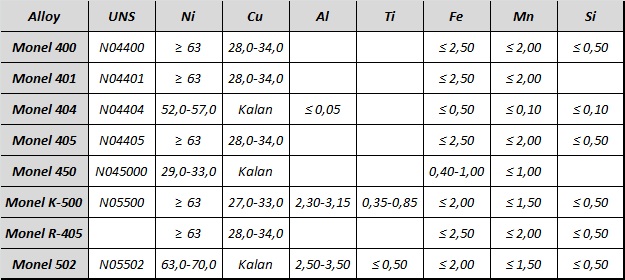

How many types of Monel alloy are there?

Monel alloys differ according to their mechanical properties.

Monel 400: It is approximately 67% Ni and 30% Cu alloy. It displays high strength and excellent corrosion resistance in a variety of acidic and alkaline environments and is particularly suitable for mitigating conditions. It also has good ductility and thermal conductivity. Monel 400 typically finds application in marine engineering, chemical and hydro-carbon processes, heat exchangers, valves and pumps. It is slightly magnetic. Monel 400 is a very remarkable Monel alloy. Its alloy has a specific gravity of 8.80 (g / cm³), a melting range of 1300-1350 ° C, an electrical conductivity of approximately 34% IACS and a Rockwell B hardness of 65 (annealed). It maintains its toughness in an important temperature range. It has excellent mechanical properties at sub-zero temperatures. Monel 400 strength and stiffness increases with only slight ductility or deterioration in impact resistance. Even when the alloy is brought to liquid hydrogen temperature, it does not change from ductility to brittle. This is in contrast to many iron-based materials that are brittle at low temperatures despite increased strength.

Monel 401: It is a slightly lower nickel Ni-Cu alloy. Used in charged parts working in sulfuric acid solutions. This alloy is designed for use in specific electrical and electronic applications. Monel 401 is easily welded automatically by the gas-tungsten-arc process. Resistance welding is a very satisfactory method of joining the material. It also exhibits good soldering properties. It is covered by the standard UNS N04401.

Monel 404: Used for non-magnetic and special electrical-electronic applications. The composition of Monel 404 is carefully adjusted to provide a very low Curie temperature, low permeability and good soldering properties. Monel 404 can be welded and forged using common welding techniques, but not hot machined. Cold working can be done using standard tools and soft mold materials to obtain a better surface. It is covered by UNS N04404 and ASTM F96 standards. This alloy is used in capsules for transistors and in ceramic to metal sealing applications.

Monel 405: It is the easily machined version of Monel 400 alloy. The percentage of nickel, carbon, manganese, iron, silicon, and copper is the same as Alloy 400. While only the sulfur ratio is "0.024 maximum", it changes to "0.025-0.060". Monel 405 is mainly used for auto screw machine stock and is generally not recommended for other applications. The nickel-copper sulphides caused by the sulfur in its composition act as chip breakers, but the surface quality of the alloy is not as smooth as Monel 400 due to these residues. Monel 405 is also called UNS N04405 and is covered by the standards ASME SB-164, ASTM B-164, Federal QQ-N-281, SAE AMS 4674 & 7234, Military MIL-N-894 and NACE MR-01-75.

Monel 450: This alloy exhibits good fatigue strength and has a relatively high thermal conductivity. It is used for seawater condensers, condenser plates, distillation pipes, evaporator and heat exchanger pipes and brine pipes.

Monel K-500: Monel K-500 is an alloy that has added properties such as greater strength and hardness to the excellent corrosion resistance characteristic of Monel Alloy 400 material. These additional properties are achieved by adding aluminum and titanium to the nickel-copper base and heating it under controlled conditions. Thus, Ni3 (Ti, Al) sub-microscopic particles are precipitated throughout the matrix. The corrosion resistance of Monel K-500 alloy is largely equivalent to Monel 400. The only difference is that in the age-hardened state K-500 alloy has a greater tendency to stress-corrosion cracking in some environments. Monel K-500 has also been found resistant to acidic gas environments. The combination of very low corrosion rate and high strength in high flow seawater makes the Monel K500 alloy particularly suitable for shafts of marine centrifugal pumps. In stagnant seawater, deposit formation and subsequent pitting may occur. However, this pitting slows down after a very rapid first attack. Typical applications for Monel K500 alloy are pump shafts and impellers, doctor blades and doctor blades, oil well weight pipes and tools and electronic components.

Monel R-405: Monel R-405 is an easily machined version of Monel 400 alloy. It is a nickel-copper alloy with a controlled amount of sulfur added to provide sulfides that act as chip breakers during machining. Like Monel 400, R-405 alloy is resistant to salt and caustic solutions as well as seawater and steam at high temperatures. Monel R-405 is a solid solution alloy that can only be hardened by cold working. This nickel alloy exhibits properties such as good corrosion resistance, good weldability and high strength. The low corrosion rate in fast-flowing seawater, combined with its excellent resistance to freshwater stress corrosion cracking and its resistance to other corrosive conditions, results in wide use in marine applications and other non-oxidizing chloride solutions. As would be expected from the high copper content, the R-405 alloy is quickly attacked by nitric acid and ammonia systems. Monel R-405 is mainly used for auto screw machine stock and is generally not recommended for other applications.

Monel 502: Monel 502 is a nickel-copper alloy and its UNS number is N05502. This grade also has good creep and oxidation resistance. Monel 502 can be created in different ways. Monel 502 can be machined similarly to austenitic stainless steels.